Factory making Revolving Tailstock Chuck - Hole back 6,8,10,12 Inches Raw Jaws – LIYUANXIN

Factory making Revolving Tailstock Chuck - Hole back 6,8,10,12 Inches Raw Jaws – LIYUANXIN Detail:

Product Description

We put the parts of the processing craft route, process parameters and tool trajectory, displacement, cutting parameters (spindle revolutions, feeding, turning back, etc.) as well as the auxiliary function (in knife, spindle forward, reverse, cutting fluid, etc.), according to the regulations of the nc machine tool of instruction code and program format to compile processing orders, Then the contents of the program are recorded on the control medium (such as punched paper tape, magnetic tape, disk, magnetic bubble memory), and then input to the numerical control device of the CNC machine tool, so as to command the machine tool to process parts.

| Place of Origin | Jiangsu, China |

| Applicable Machine | Precision Milling |

| Machine Material | Steel |

| Application | CNC Lathe Machine |

| Usage | Multipurpose |

| Feature | High Precision |

| Machine Type | CNC Lathe Machine |

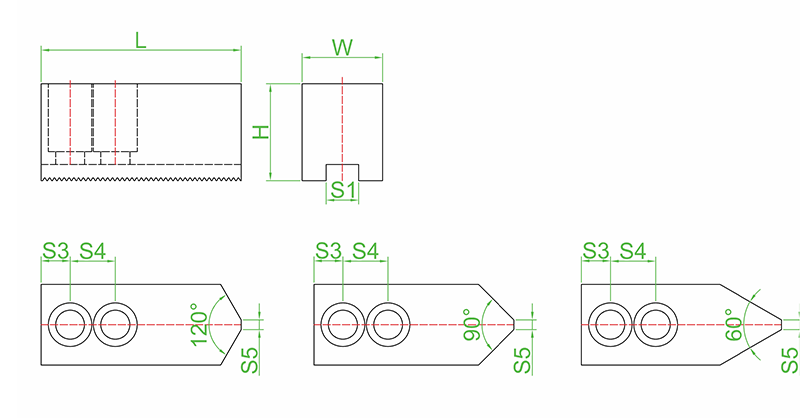

Product Parameters

| Model | L | W | H | S1 | S3 | S4 | S5 | Weight kg/set |

| 06H36 | 73 | 31 | 36 | 12 | 10 | 20 | 3 | 1.8 |

| 06H50 | 73 | 31 | 50 | 12 | 10 | 20 | 3 | 2.2 |

| 06H60 | 73 | 31 | 60 | 12 | 10 | 20 | 3 | 2.5 |

| 06H70 | 73 | 31 | 70 | 12 | 10 | 20 | 3 | 3 |

| 06H80 | 73 | 31 | 80 | 12 | 10 | 20 | 3 | 3.4 |

| 06H90 | 73 | 31 | 90 | 12 | 10 | 20 | 3 | 3.7 |

| 06H100 | 73 | 31 | 100 | 12 | 10 | 20 | 3 | 4 |

| 06H110 | 73 | 31 | 110 | 12 | 10 | 20 | 3 | 4.6 |

| 06H120 | 73 | 31 | 120 | 12 | 10 | 20 | 3 | 4.9 |

| 06H130 | 73 | 31 | 130 | 12 | 10 | 20 | 3 | 5.2 |

| 06H140 | 73 | 31 | 140 | 12 | 10 | 20 | 3 | 6 |

| 06H150 | 73 | 31 | 150 | 12 | 10 | 20 | 3 | 6.4 |

| 06H160 | 73 | 31 | 160 | 12 | 10 | 20 | 3 | 6.7 |

| Model | L | W | H | S1 | S3 | S4 | S5 | Weight kg/set |

| 08H38 | 95 | 35 | 38 | 14 | 15 | 25 | 3 | 2.7 |

| 08H50 | 95 | 35 | 50 | 14 | 15 | 25 | 3 | 3 |

| 08H60 | 95 | 35 | 60 | 14 | 15 | 25 | 3 | 4 |

| 08H70 | 95 | 35 | 70 | 14 | 15 | 25 | 3 | 4.6 |

| 08H80 | 95 | 35 | 80 | 14 | 15 | 25 | 3 | 5 |

| 08H90 | 95 | 35 | 90 | 14 | 15 | 25 | 3 | 6 |

| 08H100 | 95 | 35 | 100 | 14 | 15 | 25 | 3 | 6.7 |

| Model | L | W | H | S1 | S3 | S4 | S5 | Weight kg/set |

| 10H42 | 110 | 40 | 42 | 16 | 20 | 30 | 3 | 4 |

| 10H50 | 110 | 40 | 50 | 16 | 20 | 30 | 3 | 4.6 |

| 10H60 | 110 | 40 | 60 | 16 | 20 | 30 | 3 | 5.3 |

| 10H70 | 110 | 40 | 70 | 16 | 20 | 30 | 3 | 6.2 |

| 10H80 | 110 | 40 | 80 | 16 | 20 | 30 | 3 | 7 |

| 10H90 | 110 | 40 | 90 | 16 | 20 | 30 | 3 | 8 |

| 10H100 | 110 | 40 | 100 | 16 | 20 | 30 | 3 | 8.7 |

| Model | L | W | H | S1 | S3 | S4 | S5 | Weight kg/set |

| 12H50 | 129 | 50 | 50 | 21/18 | 25 | 30 | 6 | 6.5 |

| 12H60 | 129 | 50 | 60 | 21/18 | 25 | 30 | 6 | 7.7 |

| 12H70 | 129 | 50 | 70 | 21/18 | 25 | 30 | 6 | 9 |

| 12H80 | 129 | 50 | 80 | 21/18 | 25 | 30 | 6 | 10 |

| 12H90 | 129 | 50 | 90 | 21/18 | 25 | 30 | 6 | 11.8 |

Our Service

1, The standard soft jaws material is high quality 45# steel, good strength, can harden.

2, precision tooth spacing closely fit chuck jaw, reduce wear.

3, can be used for all other brands related to the type of chuck.

4, customized non-standard claws can be designed, customized, OEM OEM.

5. We can design jaws suitable for customers according to their product requirements

Our company’s commitment:

1. Customer inquiries within 24 hours to respond.

2. We will check carefully before shipment and choose strong packing to ensure no damage in transit.

3. Once there is a quality problem you can contact us at any time we will actively help you deal with.

Product detail pictures:

Related Product Guide:

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for Factory making Revolving Tailstock Chuck - Hole back 6,8,10,12 Inches Raw Jaws – LIYUANXIN , The product will supply to all over the world, such as: Iran, UAE, Durban, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our to meet your needs.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.