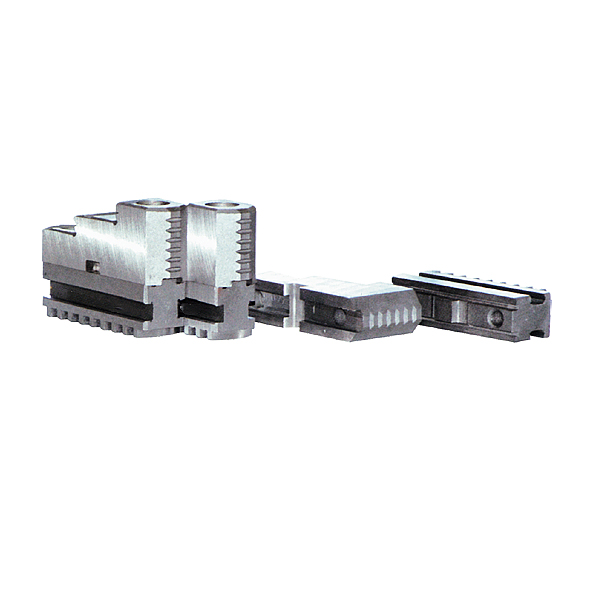

Hot-selling Cnc Soft Jaws - Hydraulic Three-jaw Chuck Oil Pressure Raw Jaws And High Soft Jaws 5 6 8 10 12 15 Inch 60 90 120 Degrees Integral Molding A Wide Range Of Applications, Stability, Accuracy, Wear And Durability – LIYUANXIN

Hot-selling Cnc Soft Jaws - Hydraulic Three-jaw Chuck Oil Pressure Raw Jaws And High Soft Jaws 5 6 8 10 12 15 Inch 60 90 120 Degrees Integral Molding A Wide Range Of Applications, Stability, Accuracy, Wear And Durability – LIYUANXIN Detail:

Product Description

The working procedure of CNC machine tool. In CNC lathe processing should go through the following steps:

1. Preparation phase. Determine relevant MACHINING DATA (tool trajectory coordinates, machining and CUTTING parameters, tool size information, etc.) according to the drawings of machining parts. And according to the process scheme, selected fixture and tool type to select other auxiliary information.

2. Programming stage. According to the machining process information, write the NC machining program (machining process description) in the language that can be recognized by the NC machine tool system, and fill in the program sheet.

3. Prepare information carriers. According to the compiled program list, the program is stored in the information carrier (punch tape, tape, disk, etc.). All the processing information is transmitted to the NC system through the information carrier. If the CNC machine is connected to a computer, the information can be loaded directly into the CNC system.

4. Processing stage. When executing the program, the NC system of the machine tool decodes the program statements, converts them into action instructions, and drives the moving parts. Under the unified coordination of the system, the driving moving parts move in time and the workpiece is processed automatically.

Product Parameters

| Origin | Jiangsu, China |

| Suitable machine | Precision milling machine |

| Material | High quality steel |

| Treatment | Vacuum heat treatment |

| Application | CNC lathe machine, machining center, various precision machine tools |

| Usage | Versatile |

| Features | High precision |

Our Service

Our company’s commitment:

1. We reply to customer inquiry within 24 hours.

2. We will carefully check before shipment, and choose strong packaging and transportation mode suitable for your company to ensure that there will be no damage during transportation.

3. Once you have quality problems, you can contact us at any time, and we will actively help you deal with them.

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good high quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Hot-selling Cnc Soft Jaws - Hydraulic Three-jaw Chuck Oil Pressure Raw Jaws And High Soft Jaws 5 6 8 10 12 15 Inch 60 90 120 Degrees Integral Molding A Wide Range Of Applications, Stability, Accuracy, Wear And Durability – LIYUANXIN , The product will supply to all over the world, such as: Puerto Rico, Anguilla, Denver, On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the high quality products with lower price. We've been looking forward to doing business with you!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.