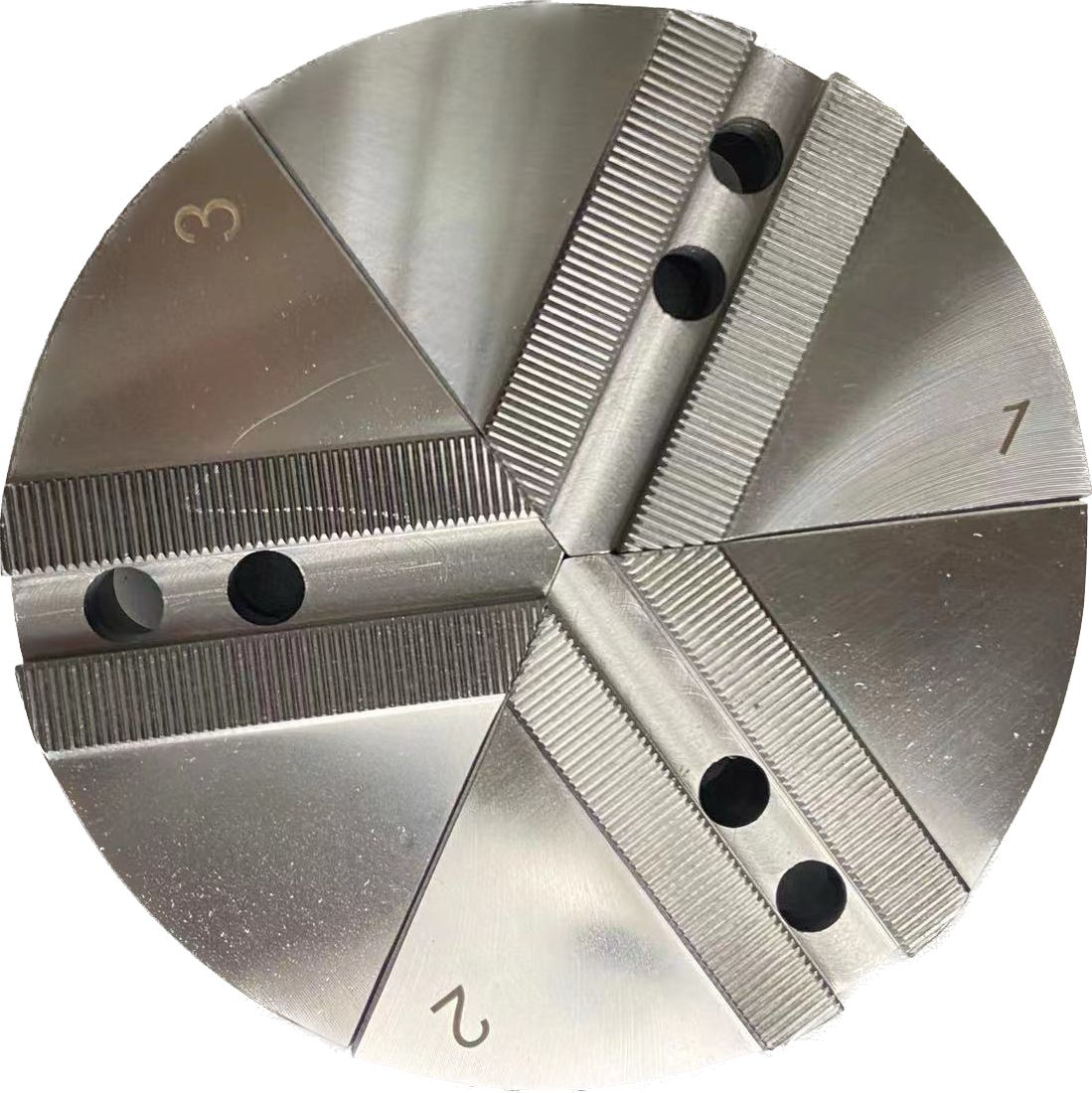

Hydraulic chuck three jaws soft jaws hydraulic jaws hydraulic raw jaws hard jaws raised 6 8 10 12 15 24

Product Parameters

| Origin | Jiangsu, China |

| Suitable machine | Precision milling machine |

| Material | High quality steel |

| Treatment | Vacuum heat treatment |

| Application | CNC lathe machine, machining center, various precision machine tools |

| Usage | Versatile |

| Features | High precision |

Our Service

Our company's commitment:

1. Reply to customer inquiry within 24 hours.

2. We will check carefully before shipment and choose strong packing to ensure no damage in transit.

3. Once you have quality problems, you can contact us at any time, and we will actively help you deal with them.

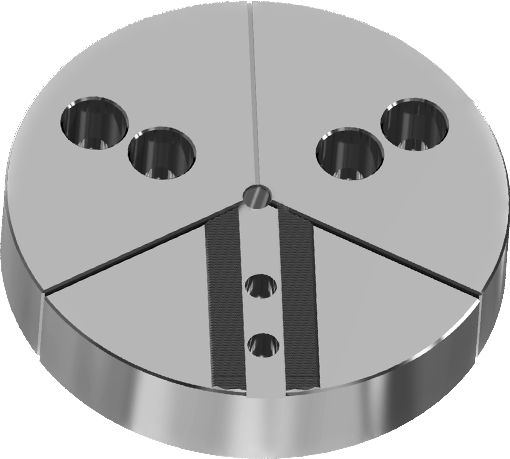

Hydraulic chuck jaw trimmer soft jaw raw jaw two jaw three jaw four jaw forming ring pneumatic chuck boring jaws 6 inch 8 inch

Product Description

The corrector forming circle is to synchronise the concentricity of the three hydraulic jaws in the jaws of the jaws repair machine, it must be necessary to fix three screws in the hydraulic jaws to synchronise a circle of holes inside the hydraulic force is adjusted to 5-8 kg pressure to increase the concentricity of the hydraulic chuck to do the necessary equipment for hydraulic lathes.

Product Parameters

| Origin | Jiangsu, China |

| Suitable machine | Precision milling machine |

| Material | High quality steel |

| Treatment | Vacuum heat treatment |

| Application | CNC lathe machine, machining center, various precision machine tools |

| Usage | Versatile |

| Features | High precision |

Our Service

Our company's commitment:

1. Reply to customer inquiry within 24 hours.

2. We will check carefully before shipment and choose strong packing to ensure no damage in transit.

3. Once you have quality problems, you can contact us at any time, and we will actively help you deal with them.

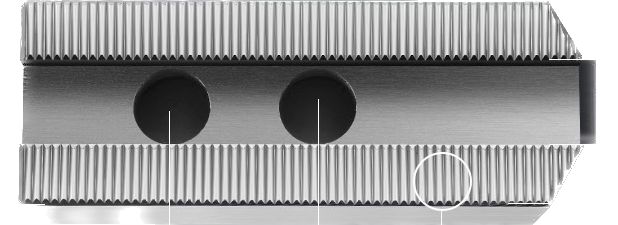

Hydraulic chuck three jaws raw jaws soft jaws 6 inch 8 inch 10 inch 12 heightened and thickened lathe hydraulic chuck jaws

Product Description

When turning the soft jaws, in order to eliminate the gap, it is necessary to install an appropriate diameter of the drawing column or ring inside or outside the jaws. They should be installed in the position of the soft jaws, and the workpiece clamping direction is consistent, otherwise the workpiece positioning accuracy can not be guaranteed.

Product Parameters

| Place of Origin | Jiangsu, China |

| Applicable Machine | Precision Milling |

| Machine Material | Steel |

| Application | CNC Lathe Machine |

| Usage | Multipurpose |

| Feature | High Precision |

| Machine Type | CNC Lathe Machine |

Our Service

1, The standard soft jaws material is high quality 45# steel, good strength, can harden.

2, precision tooth spacing closely fit chuck jaw, reduce wear.

3, can be used for all other brands related to the type of chuck.

4, customized non-standard claws can be designed, customized, OEM OEM.

5. We can design jaws suitable for customers according to their product requirements

Our company's commitment:

1. Customer inquiries within 24 hours to respond.

2. We will check carefully before delivery and choose strong packing to ensure damage in transit.

3. Once there is a quality problem you can contact us at any time we will actively help you deal with.

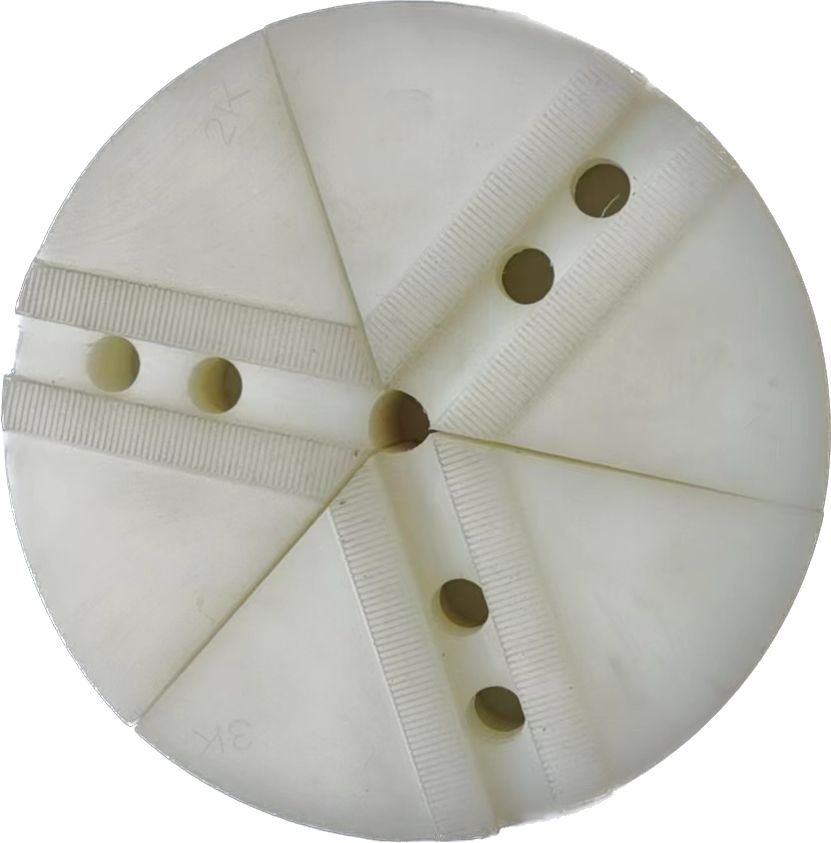

Hydraulic chuck fan chuck jaws fully wrapped soft jaws raised three jaws 5/6" 8" 10" 12" non-standard custom soft jaws

Product Description

Soft jaws chuck clamping has been processed surface or soft metal, not easy to clip the surface. For the thin wall workpiece, can be used to increase the contact area with the workpiece and reduce the deformation of the workpiece. The soft jaws chuck is suitable for the processed surface as the positioning precision benchmark, in mass production of the workpiece of the semi-precision car and the precision car.

Product Parameters

| Place of Origin | Jiangsu, China |

| Applicable Machine | Precision Milling |

| Machine Material | Steel |

| Application | CNC Lathe Machine |

| Usage | Multipurpose |

| Feature | High Precision |

| Machine Type | CNC Lathe Machine |

Product Parameters

| Model | ∅W | B | J | G | H | ∅A | ∅B | ||||

| 05 | 128 | 10 | 14 | 10 | 30 | 9 | 14 | ||||

| 06 | 158 | 15 | 20 | 12 | 36 | 11 | 18 | ||||

| 08 | 208 | 24 | 25 | 14 | 37 | 13 | 20 | ||||

| 10 | 248 | 25 | 30 | 16 | 42 | 13 | 20 | ||||

| 12 | 300 | 35 | 30 | 21/18 | 50 | 18 | 26 | ||||

| 15 | 380 | 37 | 43 | 22/25.5 | 62 | 22 | 32 | ||||

| Model | ∅W | B | J | G | H | ∅A | ∅B | ||||

| 05H | 128 | 10 | 14 | 10 | 40/50/60/70 | 9 | 13.5 | ||||

| 06H | 158 | 15 | 20 | 12 | 40/50/60/70 | 11 | 17 | ||||

| 08H | 208 | 24 | 25 | 14 | 50/60/70/80 | 13 | 19 | ||||

| 10H | 248 | 25 | 30 | 16 | 60/70/80/90 | 13 | 19 | ||||

| 12H | 300 | 35 | 30 | 21/18 | 60/70/80/90 | 17/15 | 25/23 | ||||

| 15H | 380 | 37 | 43 | 22/25.5 | 70/80/90/100 | 21 | 32 | ||||

Our Service

1, The standard soft jaws material is high quality 45# steel, good strength, can harden.

2, precision tooth spacing closely fit chuck jaw, reduce wear.

3, can be used for all other brands related to the type of chuck.

4, customized non-standard claws can be designed, customized, OEM OEM.

5. We can design jaws suitable for customers according to their product requirements

Our company's commitment:

1. Customer inquiries within 24 hours to respond.

2. We will check carefully before shipment and choose strong packing to ensure no damage in transit.

3. Once there is a quality problem you can contact us at any time we will actively help you deal with.