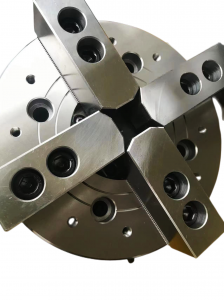

Four-jaw Hydraulic Chuck Or 4 Jaw Hydraumatic Chuck From China Supplier For Lathe Chuckthree Jaw Hydraulic Chuck For Lathe Machine Comprehensive Specifications And Models

Product Description

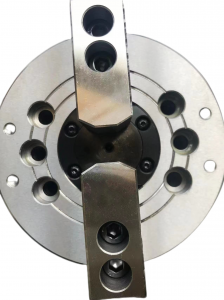

One is a backpull hydraulic chuck that is, the chuck is installed in the front end of the lathe spindle, and the rotary hydraulic cylinder is installed in the rear end of the lathe spindle. This installation waterproof cutting fluid ability is very good. workpiece.

We give a hydraulic chuck locking command on the system, System would like to send commands to PLC, PLC control relay action, relay, and so did the solenoid valve action - hydraulic oil movement direction and then change the rotary cylinder piston - which in turn led to laguan - before and after exercise tubing connection with hydraulic chuck - let the inside of the chuck a wedge body axial movement into the radial motion - OK.

If you give a hydraulic chuck square loose command from the system, change the flow direction of hydraulic oil, you can achieve the full reverse action.

Hollow hydraulic chuck with oil cylinder or cylinder as power source, suitable for ordinary lathes, CNC lathes and other series of lathes, the material is completely made of 45# steel quenching and tempering treatment, improve the hardness of the disc, mechanical properties, increase the total disk life. Hollow hydraulic chuck adopts advanced equipment and strict process, with the advantages of good safety, convenient operation, quick use, high precision, not only improve production efficiency and reduce labor intensity. Professional fixture to meet the needs of current machining industry.

Product Parameters

| Origin | Jiangsu, China |

| Suitable machine | Precision milling machine |

| Material | High quality steel |

| Treatment | Vacuum heat treatment |

| Application | CNC lathe machine, machining center, various precision machine tools |

| Usage | Versatile |

| Features | High precision |

Our Service

Our company's commitment:

1. We reply to customer inquiry within 24 hours.

2. We will carefully check before shipment, and choose strong packaging and transportation mode suitable for your company to ensure that there will be no damage during transportation.

3. Once you have quality problems, you can contact us at any time, and we will actively help you deal with them.