The clearance of the die is related to the type and thickness of the material being stamped. Unreasonable gaps can cause the following problems:

(1) If the gap is too large, the burr of the stamping workpiece is relatively large and the stamping quality is poor. If the gap is small, although the quality of punching is better, but the wear of the die is more serious, greatly reducing the service life of the die, and easy to cause the break of the punch.

(2) the gap is too large or too small are easy to produce adhesion on the punch material, resulting in stamping with material. Too small clearance is easy to form a vacuum between the bottom of the punch and the sheet metal and waste rebound.

(3) reasonable clearance can prolong the life of the mold, discharge effect is good, reduce burr and flanging, plate keep clean, aperture is consistent will not scratch the plate, reduce the number of grinding, keep the plate straight, accurate punching positioning.

CNC punch die, CNC punch tool, CNC die

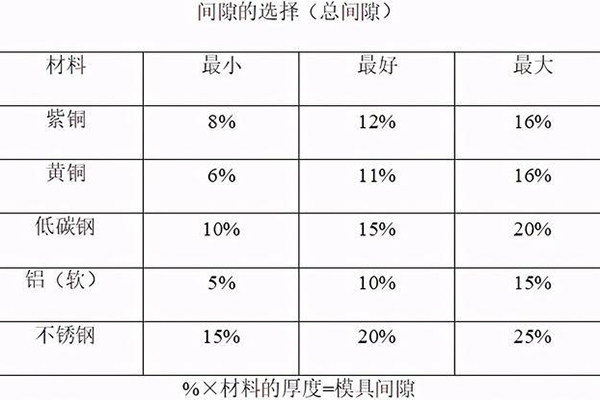

Please refer to the chart to select mold clearance (the data in the table is percentage)

(1) If the gap is too large, the burr of the stamping workpiece is relatively large and the stamping quality is poor. If the gap is small, although the quality of punching is better, but the wear of the die is more serious, greatly reducing the service life of the die, and easy to cause the break of the punch.

(2) the gap is too large or too small are easy to produce adhesion on the punch material, resulting in stamping with material. Too small clearance is easy to form a vacuum between the bottom of the punch and the sheet metal and waste rebound.

(3) reasonable clearance can prolong the life of the mold, discharge effect is good, reduce burr and flanging, plate keep clean, aperture is consistent will not scratch the plate, reduce the number of grinding, keep the plate straight, accurate punching positioning.

CNC punch die, CNC punch tool, CNC die

Please refer to the chart to select mold clearance (the data in the table is percentage)

Industry information:

1. How to judge the fault of precision NC lathe

Automatic CNC lathe industry is now facing a serious problem, is the high-end CNC machine tool imports dominate. From the relevant data of CNC machine tool imports, since November 2012, China's CNC machine tool imports as a whole show a downward trend, but the import price has been rising, which can show that high-end CNC machine tool imports continue to rise. Do not say the machine itself, CNC machine tool is the main product of machine tool automation and intelligence, the level of its CNC system is an important indicator to determine the level of automatic CNC lathe. However, 90% of domestic CNC systems have to be imported.

2. How does a CNC lathe work

CNC lathe can be configured with two kinds of knife table: (1) type knife table by the CNC lathe manufacturer's own development and design, the application of the collet is also type. The advantage of this kind of knife table is the low cost of production and manufacturing, but the lack of practicality (2) universal knife table based on the universal specification (such as VDI, French Institute of Technical Engineers) and the production of knife table, CNC lathe manufacturers can choose and equip according to the role of CNC lathe provisions. 1. The production capacity of CNC lathe can be greatly expanded after the cutting rotary table is installed on the cutting rotary table. For example, the use of rotary cutting table to carry out radial drilling and cutting axial groove. 2. CNC lathe CNC blade in CNC lathe or milling production machining center milling parts, should be based on the CNC lathe structure and can be installed on the total number of CNC blade, effective and scientific research to allocate NC blade on the tool table parts, and pay attention to prevent CNC blade in static and work, The interference between NC blade and NC lathe, NC blade and workpiece and its NC blade.

The work can be roughly divided into the following processes: 1. Carry out numerical calculation methods and processing techniques according to the production and processing technical content specified in the part drawings. Distribution and program flow design. 2. The numerical control machine tool program flow according to the numerical control lathe requirements of the program flow file format, and detailed record in the way of coding on the mobile storage equipment, according to the input (manual production, electronic computer transmission, etc.) method, the content of the production and processing program flow to the numerical control machine tool equipment. 3. The NC machine tool program flow (NC code) accepted by the NC machine tool, NC code is converted into or manually made by the software programmer in CAM software, she is a text data information, the expression is more visual, easier to be immediately understood by the software programmer, but can not be immediately applied for hardware configuration. NC machine tool NC equipment coded "Chinese translation" for coding equipment, equipment coding is a composed of 0 s and 1 s of binary files, then transform to manipulate X and Z direction fitness data signal pulse current, and other auxiliary data signals, and solutions in the form of differential signal to the output port of NC machine tool equipment, servo control system to carry out the practice.

3. In the rainy season, how should automatic CNC lathes be maintained

In the rainy season, the maintenance and maintenance of mechanical equipment is very important, because in such weather, equipment is more prone to failure, and many areas of southern China have heavy rainfall, and even some areas have floods. Here, we introduce how to maintain the automatic CNC lathe in the rainy season?

Automatic CNC lathe is a precision production tool, it has the following three main requirements for the environment:

(1) place the position of automatic CNC lathe to the principle of vibration source, and can not have direct sunlight, air is also required to dry;

(2) Requirements for power supply, power supply voltage must be stable;

(3) Temperature and humidity requirements, the temperature should not be less than 30℃, humidity should not be less than 80%. Why do we need such conditions? Let xiaobian to clear up the confusion for you: the first vibration will directly affect the quality of the workpiece, long time of sunlight exposure to the accuracy control of automatic CNC lathe is also affected; Secondly, the voltage stability of the power supply is one of the important factors to ensure the normal work of the automatic CNC lathe, because the components of the automatic CNC lathe are also precision parts, voltage instability is easy to cause damage to precision parts, resulting in automatic CNC lathe can not work properly; After, temperature and humidity is also an important factor to ensure the normal operation of automatic CNC lathe components, too high temperature and humidity will lead to reduced life of system components, increased failure, and even make dust bond on the circuit board, resulting in a short circuit.

Strictly abide by the electricity code

1. The automatic CNC lathe must be strictly required to access the ground, and the use of three-core power plug, reduce electrostatic interference, improve the stability of the machine and the protection of the operator. In summer, due to excessive power consumption and rainy season, there will often be power supply line voltage instability, etc., resulting in failure, and even burn the driver and other components. It is recommended to purchase the voltage regulator of the corresponding model.

2. Improve CNC automatic use of CNC lathe, CNC numerical control lathe if running rate is not high, in addition to the money, the effect was less than reproduction, but also worry about a thing is the warranty period, because the CNC automatic CNC lathe equipment it has a warranty period, the user should use machine in this period, the thin part exposed as soon as possible, To be disposed of under warranty. If not used for a long time, the deterioration or damage of electronic components may be accelerated due to damp and other reasons. Especially in the rainy season, also want to run the machine properly.

3. CNC automatic CNC lathe should be used in a good environment because the air is humid in the rainy season. It is easy to be damp in the humid air and fail. And pay attention to details at work, so be careful not to bring umbrellas to the production site, change shoes, etc.

4. What are the key components of the automatic CNC lathe machini

1, Automatic CNC lathe spindle bearing box: machining center spindle bearing box fixed in the upper left end of the bed. It transmits the rotating fitness movement of the motor to the spindle bearing, and pushes the workpiece to rotate together according to the fixture. By changing the rocker position on the box, the spindle bearing can obtain a variety of speed ratios of positive and reverse.

2, Tool box: the tool box of the machining center is fixed in the left front and bottom of the bed. According to the hanging wheel, the rotating fitness movement of the spindle bearing is transmitted to the ball screw or light screw. Change the rocker position on the box, can change the speed ratio of ball screw or light screw, and then achieve the goal of changing the tooth pitch or cutting speed.

3, Slide board box: slide board box fixed on the outside of the bed saddle, with the bed saddle together in the bed body slide rail for vertical repeated movement. According to it the ball screw or light bar rotation fitness into a bed saddle, double warped plate walking knife fitness. The rocker part on the conversion box can operate the lathe tool's vertical or horizontal fitness movement (fitness movement orientation, start or stop).

4. Side rack: Side rack is installed on the left side of the bed. It is equipped with an interchangeable transmission gear (hanging wheel), which transmits the rotary fitness movement of the spindle bearing to the tool box. Adjust the transmission gear on the rack of the hanging wheel and cooperate with the cutter box to mill threads with different pitch.

5, Knife table: knife table fixed in the small drag pull, used for weapons and equipment lathe tool.

6, Precision CNC lathe pallet: pallet includes bed saddle, double warping plate, wheel and small double warping plate four parts. The bed saddle is mounted on the slide rails outside the bed body and can be moved vertically along the slide rails of the bed body. The double warping plate can move horizontally along the dovetail slide rail at the upper end of the bed saddle; The small double warping plate can move vertically along the dovetail slide rail at the top of the wheel. After the wheel rotates for one Angle of view, the small double warping plate can push the knife to move diagonally, which is used for milling short internal and external conical surfaces.

7, Lathe tool rest: the tail seat is installed on the bed body group slide rail, and can be moved vertically along the bed body slide rail. The cone hole of the sleeve specification on the lathe tool holder can be installed, twist drill, reamer, tap and other knives and accessories, used to support the product workpiece, drilling, boring, tapping and so on.

8, Bed body: bed body is the foundation of CNC lathe support. It is fixed on the left and right bed legs, used to support the key components of the lathe side, and make them maintain difficult relative position in the work. Two groups of slide rails on the bed body provide guidance for the vertical movement of the bed saddle and lathe tool rest.

9, Ball screw: ball screw key for milling thread, is one of the key fine parts of the lathe edge. In order to always maintain the precision of the ball screw, it is generally not necessary to use the ball screw for automatic cutting.ng center?

Post time: Aug-12-2022