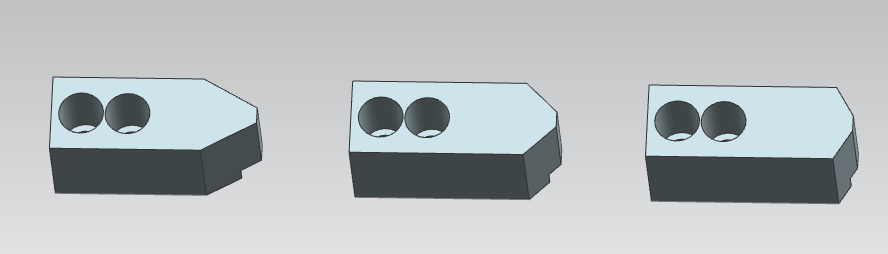

OEM/ODM China Vice Soft Jaws - Hydraulic Three-jaws Chuck 120 Degrees Pointed Soft Jaws And High Raw Jaws Lengthening Soft Jaws Widening Oil Pressure 6 “8″ 10 “jaws Fine Workmanship Without Burr Can Be Trimmed Not Easy Deformation – LIYUANXIN

OEM/ODM China Vice Soft Jaws - Hydraulic Three-jaws Chuck 120 Degrees Pointed Soft Jaws And High Raw Jaws Lengthening Soft Jaws Widening Oil Pressure 6 “8″ 10 “jaws Fine Workmanship Without Burr Can Be Trimmed Not Easy Deformation – LIYUANXIN Detail:

Product Description

For mass production, the hardness of the soft jaws will have a great impact on the stability of the processing, the choice of soft jaws material with higher hardness than the workpiece, will not only improve the service life of the soft jaws, the stability of the processing will also have a positive impact.

Make inner holes of the same size as the workpiece diameter to reduce the possibility of clamping the workpiece.

Add a retreat slot to ensure repositioning of the workpiece.

Remove burrs and sharp corners from soft PAWS (be careful not to scratch your hands).

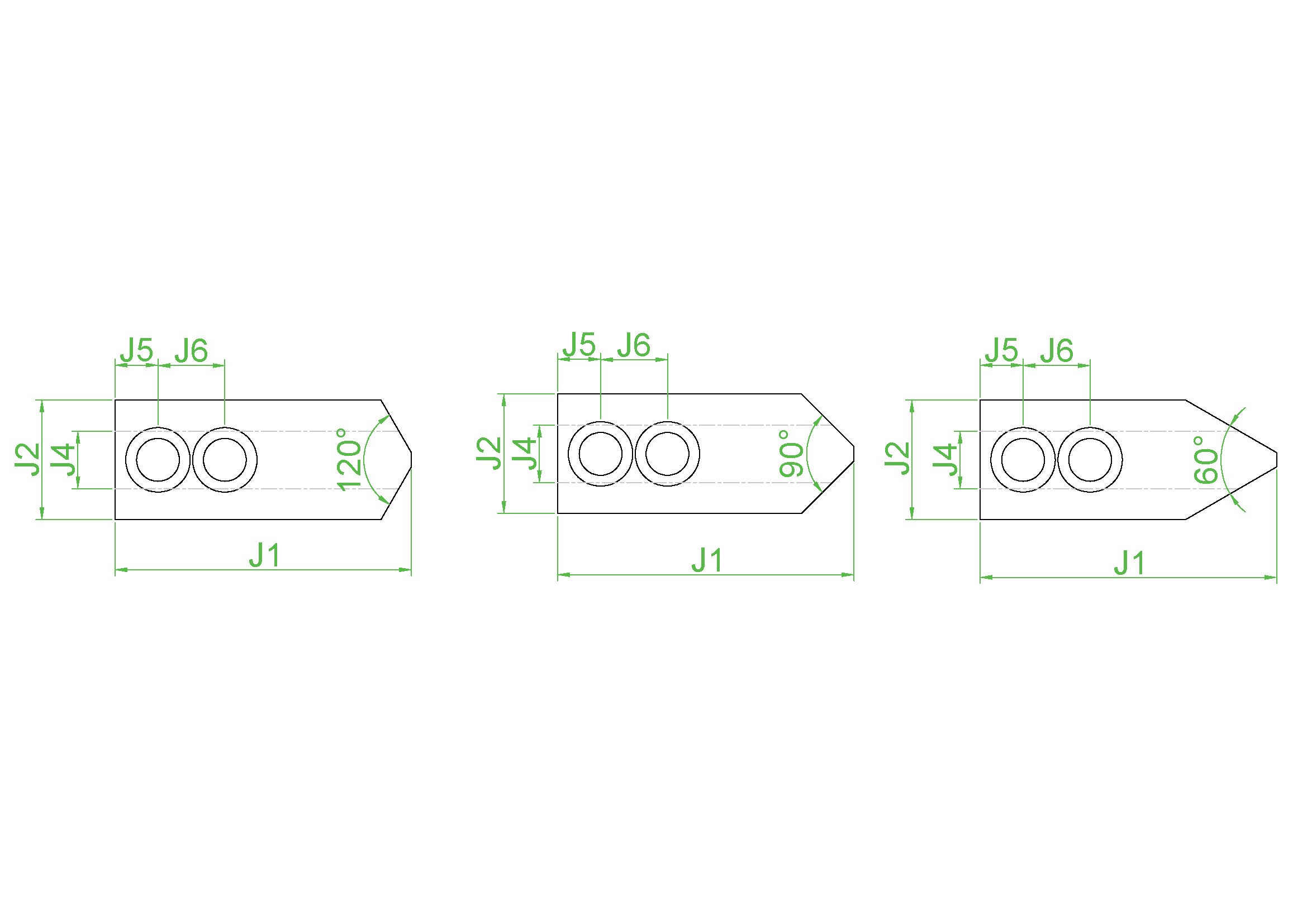

Soft claw size selection

The soft claw should hold at least 1/3 of the length of the workpiece.

can be used in Taiwan, Japan, Germany, the United States, and other relevant brands of chucks.

1.custom non-standard soft claw, hard claw, chuck claw, claw, claw, claw, automatic claw, robot finger, can be designed, customized, OEM OEM.

2.Three products for one payment, one pay independent packaging. After the product is soaked in anti-rust oil, it is packed with PE bag and paper box. By default, we usually use laser typewriter to mark numbers like 1,2,3 for convenience. We can also mark them according to the requirements of the customer’s drawings. If it is not necessary to lettering, it needs to be explained in advance.

3, the product can also be divided into two one pay, four one pay, six one pay and so on according to the customer chuck model.

Product Parameters

| Origin | Jiangsu, China |

| Suitable machine | Precision milling machine |

| Material | High quality steel |

| Treatment | Vacuum heat treatment |

| Application | CNC lathe machine, machining center, various precision machine tools |

| Usage | Versatile |

| Features | High precision |

| Model | J1 | J2 | J4 | J5 | J6 | B | screw | Weight kg/set |

| SC06H36P | 73 | 31 | 12 | 10 | 20 | 3 | M10 | 1.5 |

| SC06H50P | 73 | 31 | 12 | 10 | 20 | 3 | M11 | 1.9 |

| SC06H60P | 73 | 31 | 12 | 10 | 20 | 3 | M12 | 2.5 |

| SC06H70P | 73 | 31 | 12 | 10 | 20 | 3 | M13 | 2.9 |

| SC06H80P | 73 | 31 | 12 | 10 | 20 | 3 | M14 | 3.4 |

| SC06H90P | 73 | 31 | 12 | 10 | 20 | 3 | M15 | 3.8 |

| SC06H100P | 73 | 31 | 12 | 10 | 20 | 3 | M16 | 4 |

| SC06H110P | 73 | 31 | 12 | 10 | 20 | 3 | M17 | 4.4 |

| SC06H120P | 73 | 31 | 12 | 10 | 20 | 3 | M18 | 4.8 |

| SC06H130P | 73 | 31 | 12 | 10 | 20 | 3 | M19 | 5.2 |

| SC06H140P | 73 | 31 | 12 | 10 | 20 | 3 | M20 | 5.8 |

| SC06H150P | 73 | 31 | 12 | 10 | 20 | 3 | M21 | 6.2 |

Our Service

Our company’s commitment:

1. Reply to customer inquiry within 24 hours.

2. We will carefully check before shipment, and choose strong packaging and transportation mode suitable for your company to ensure that there will be no damage during transportation.

3. Once you have quality problems, you can contact us at any time, and we will actively help you deal with them.

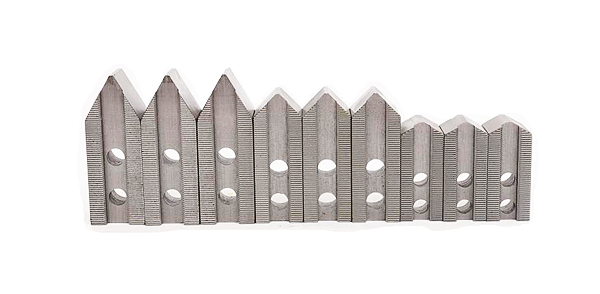

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for OEM/ODM China Vice Soft Jaws - Hydraulic Three-jaws Chuck 120 Degrees Pointed Soft Jaws And High Raw Jaws Lengthening Soft Jaws Widening Oil Pressure 6 “8″ 10 “jaws Fine Workmanship Without Burr Can Be Trimmed Not Easy Deformation – LIYUANXIN , The product will supply to all over the world, such as: Nairobi, Auckland, Marseille, We attained ISO9001 which provides solid foundation for our further development. Persisting in High quality, Prompt Delivery, Competitive Price, we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!