Quality Inspection for Jaw Chuck For Lathe - Hydraulic Chuck Three Jaws Hard Jaws Soft Claw 6 “8″ 10 “12 High Lengthen And Thickening Lathe Oil Pressure Claw Fixture Durable High Efficiency Choose High Strength 45 Steel Precision Angle Processing – LIYUANXIN

Quality Inspection for Jaw Chuck For Lathe - Hydraulic Chuck Three Jaws Hard Jaws Soft Claw 6 “8″ 10 “12 High Lengthen And Thickening Lathe Oil Pressure Claw Fixture Durable High Efficiency Choose High Strength 45 Steel Precision Angle Processing – LIYUANXIN Detail:

Product Description

In use, according to the needs of the clamping parts, the claws are temporarily clamped into the required shape with a tool on the lathe — at this time, the clamping accuracy is very high. It can also avoid clamping parts. Hard jaws is quenched, high hardness, wear resistance, strong clamping, versatility, but clamping accuracy is not high, coaxiality at least a few wire difference. Suitable for rough machining of parts. Soft jaws are suitable for the processing of precision parts, small clamping surface parts, especially in the case of a certain batch, good accuracy and high efficiency.

| Place of Origin | Jiangsu, China |

| Applicable Machine | Precision Milling |

| Machine Material | Steel |

| Application | CNC Lathe Machine |

| Usage | Multipurpose |

| Feature | High Precision |

| Machine Type | CNC Lathe Machine |

Product Parameters

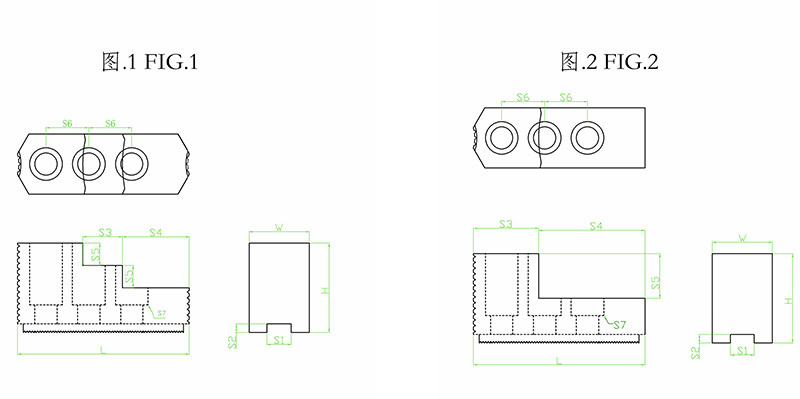

| SPEC MODEL | L | W | H | S1 | S2 | S3 | S4 | S5 | S6 | S7 | Serration Pitch | Weight kg/set | Ref |

| HJ-05 | 53 | 23 | 28 | 10 | 4 | 22.5 | 30.5 | 10 | 14 | M8 | 1.5*60° | 0.5 | Fig2 |

| HJ-06 | 67 | 31 | 36 | 12 | 5 | 28 | 39 | 12 | 20 | M10 | 1.5*60° | 1 | Fig2 |

| HJ-08 | 86 | 35 | 51 | 14 | 5 | 18 | 31 | 12 | 25 | M12 | 1.5*60° | 2 | Fig1 |

| HJ-10 | 100 | 40 | 54 | 16 | 5 | 17 | 43 | 14 | 30 | M12 | 1.5*60° | 2.7 | Fig1 |

| HJ-12 | 103 | 50 | 52 | 21 | 5 | 43.5 | 69.5 | 20 | 30 | M16(M14) | 1.5*60° | 3.7 | Fig2 |

| HJ-15 | 149 | 62 | 86 | 22 | (5)8 | 38 | 55 | 20 | 43 | M20 | 1.5*60° | 9.5 | Fig1 |

| HJ-24 | 159.5 | 80 | 90 | 25 | 9 | 55 | 104.5 | 40 | 50 | M20 | 3.0*60° | 14 | Fig2 |

| HJ-32 | 159.5 | 80 | 90 | 25 | 9 | 55 | 104.5 | 40 | 50 | M20 | 3.0*60° | 14 | Fig2 |

Our Service

1, The standard soft jaws material is high quality 45# steel, good strength, can harden.

2, precision tooth spacing closely fit chuck jaw, reduce wear.

3, can be used for all other brands related to the type of chuck.

4, customized non-standard claws can be designed, customized, OEM OEM.

5. We can design jaws suitable for customers according to their product requirements

Our company’s commitment:

1. Customer inquiries within 24 hours to respond.

2. We will check carefully before delivery and choose strong packing to ensure damage in transit.

3. Once there is a quality problem you can contact us at any time we will actively help you deal with.

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably technologically innovative, cost-efficient, and price-competitive manufacturers for Quality Inspection for Jaw Chuck For Lathe - Hydraulic Chuck Three Jaws Hard Jaws Soft Claw 6 “8″ 10 “12 High Lengthen And Thickening Lathe Oil Pressure Claw Fixture Durable High Efficiency Choose High Strength 45 Steel Precision Angle Processing – LIYUANXIN , The product will supply to all over the world, such as: Algeria, Montpellier, Greece, Our product quality is one of the major concerns and has been produced to meet the customer's standards. Customer services and relationship is another important area which we understand good communication and relationships with our customers is significant power to run it as a long term business.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.